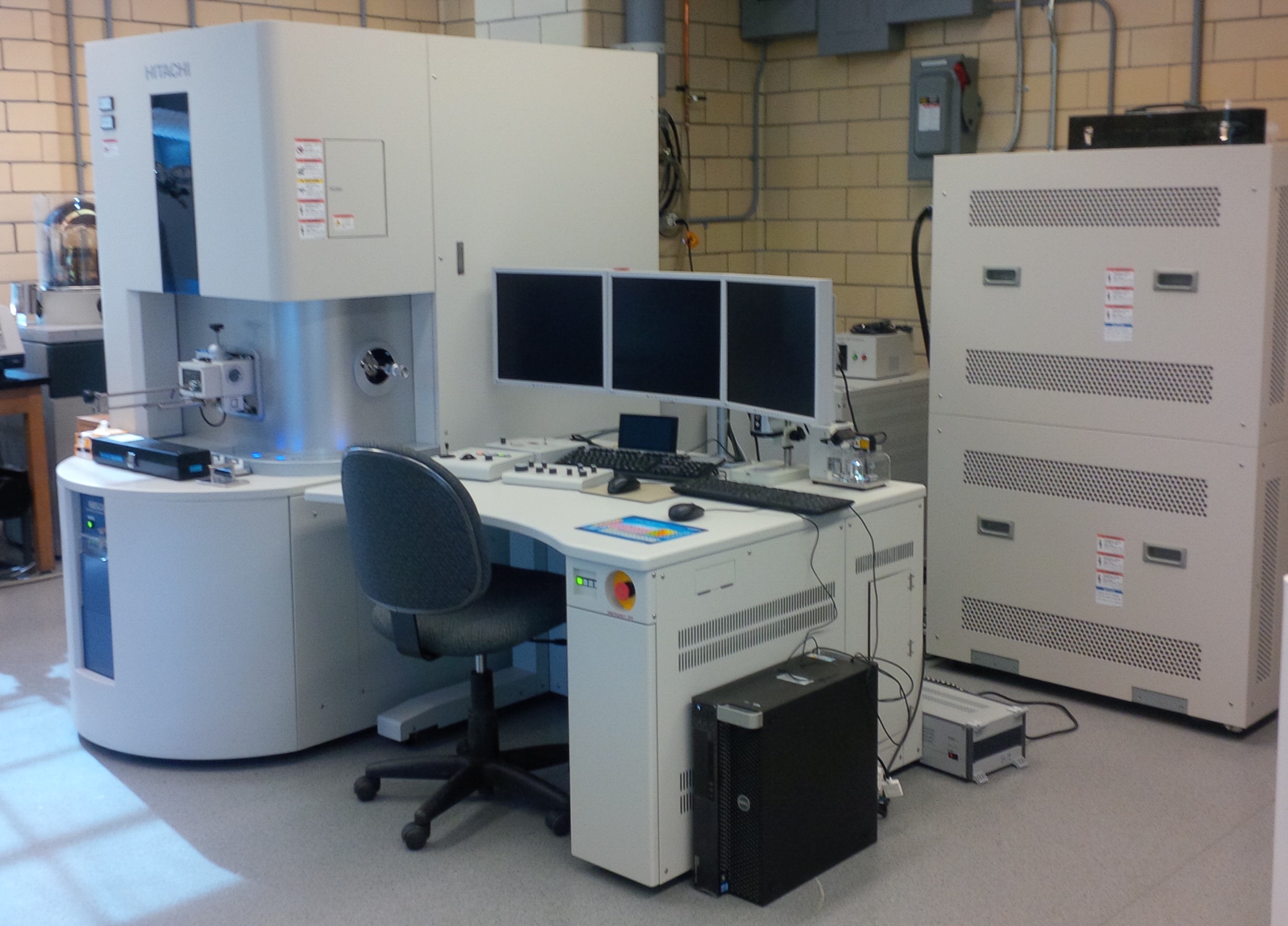

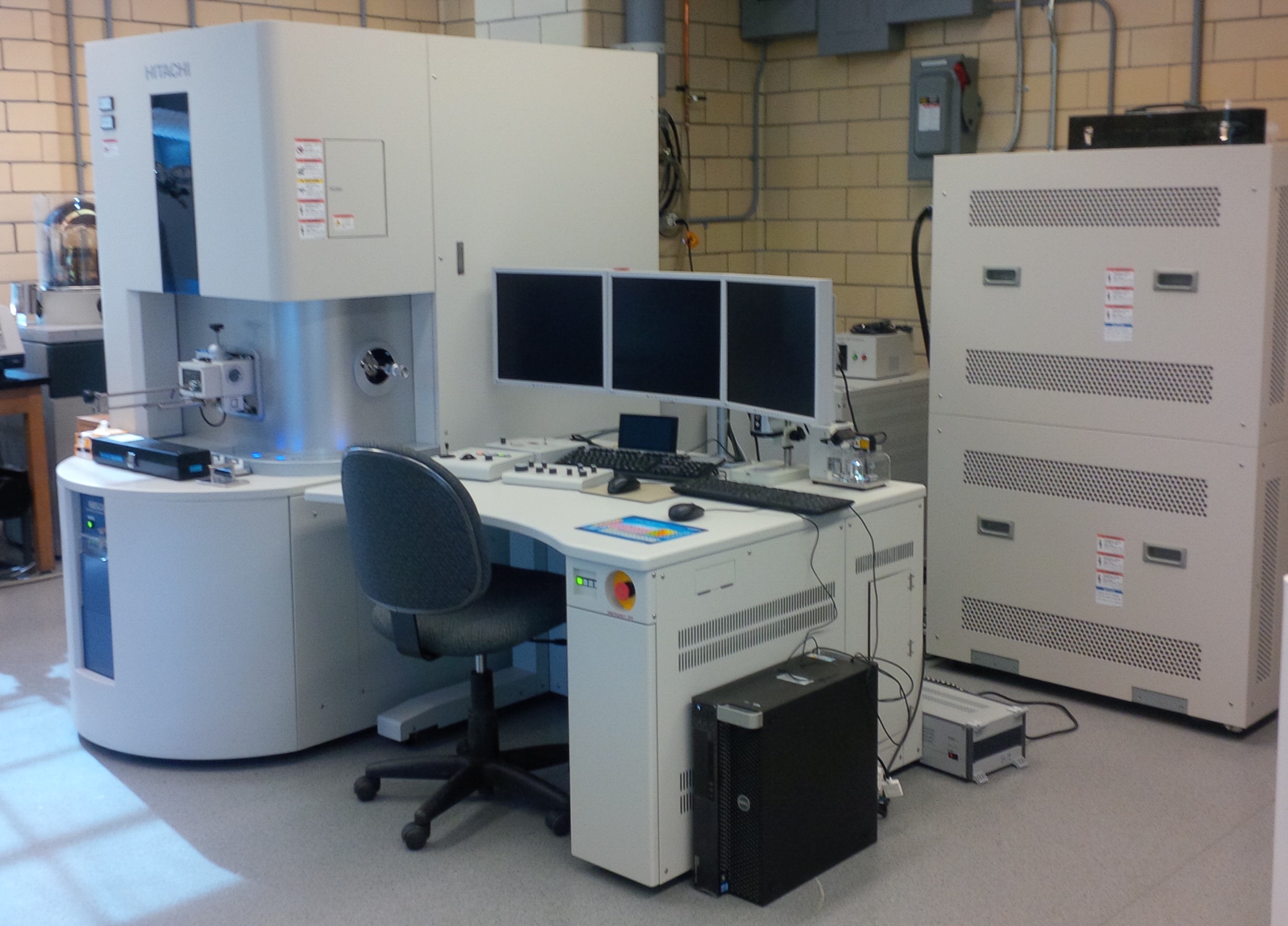

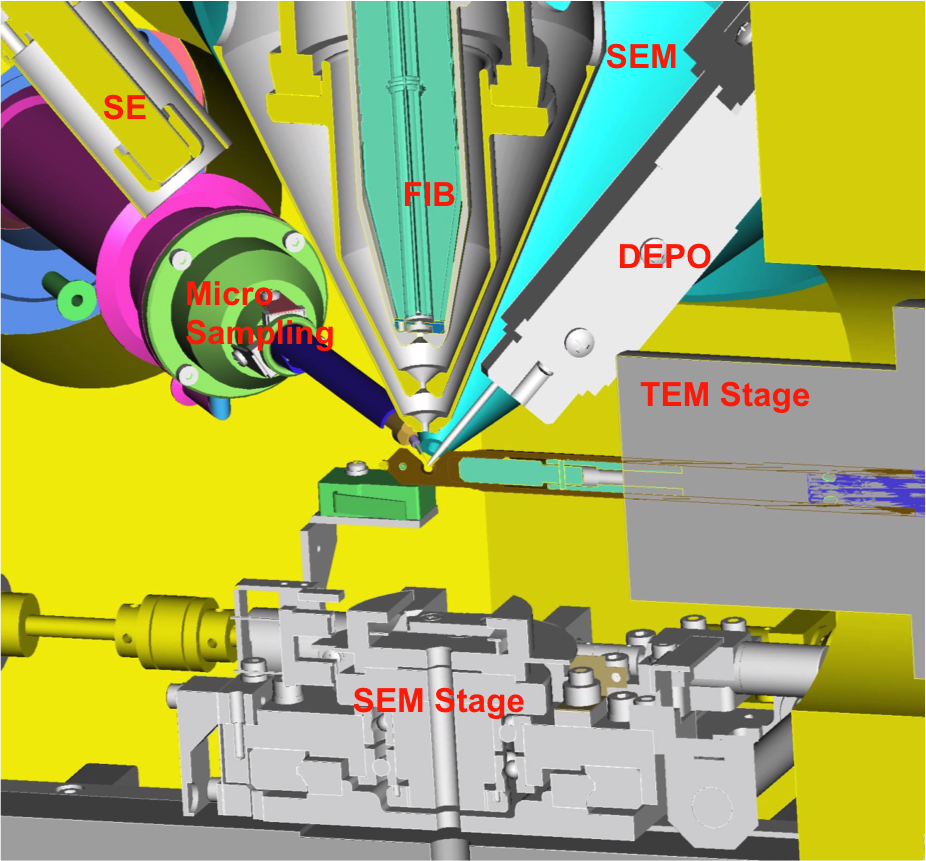

Allows for site-specific analysis, deposition, and removal of material in the micron and submicron range.

- Ultrahigh performance FIB

- Ga FIB optics

- > 50 nA max. beam current at 40kV

- Integrated Micro-sampling system

- Fully integrated lift-out system

- Absorbed current imaging

- High precision end-point detection

- Mill & Monitor

- Section-view

- Live Fabrication

- High Resolution SEM

- 1.5 nm @ 5kV, at Cross-point

- 1.0 nm @ 15kV, at Cross-point

- 0.8 nm @ 30kV, at Cross-point

- Holders compatible with TEM/STEM

|

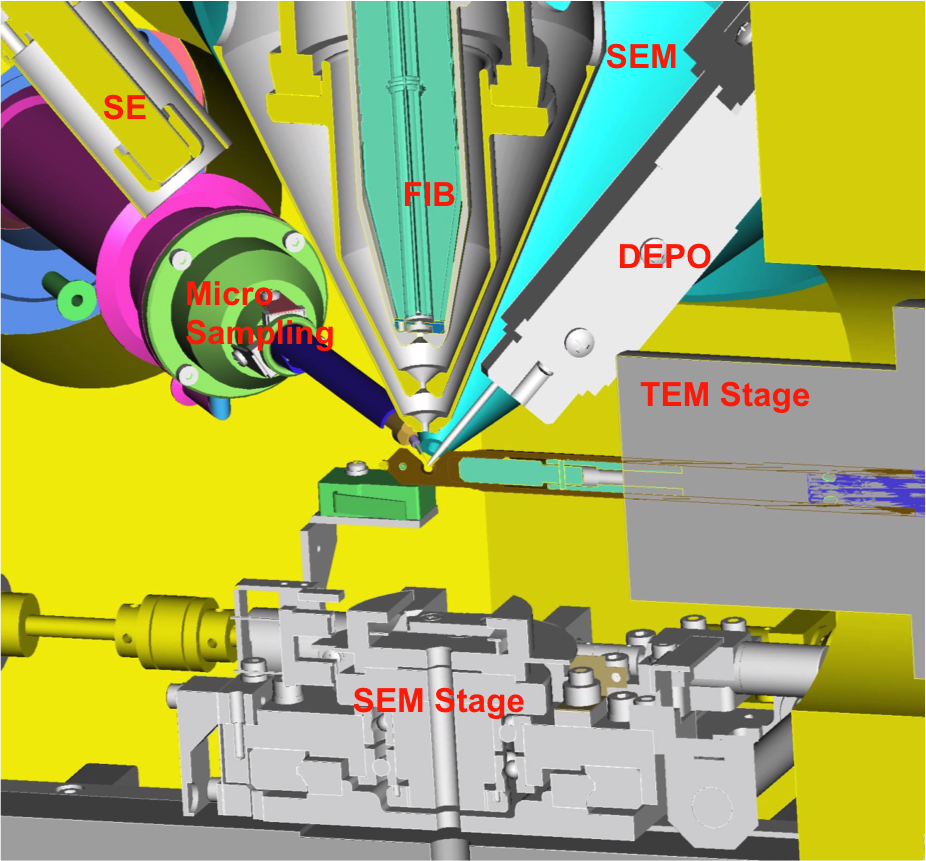

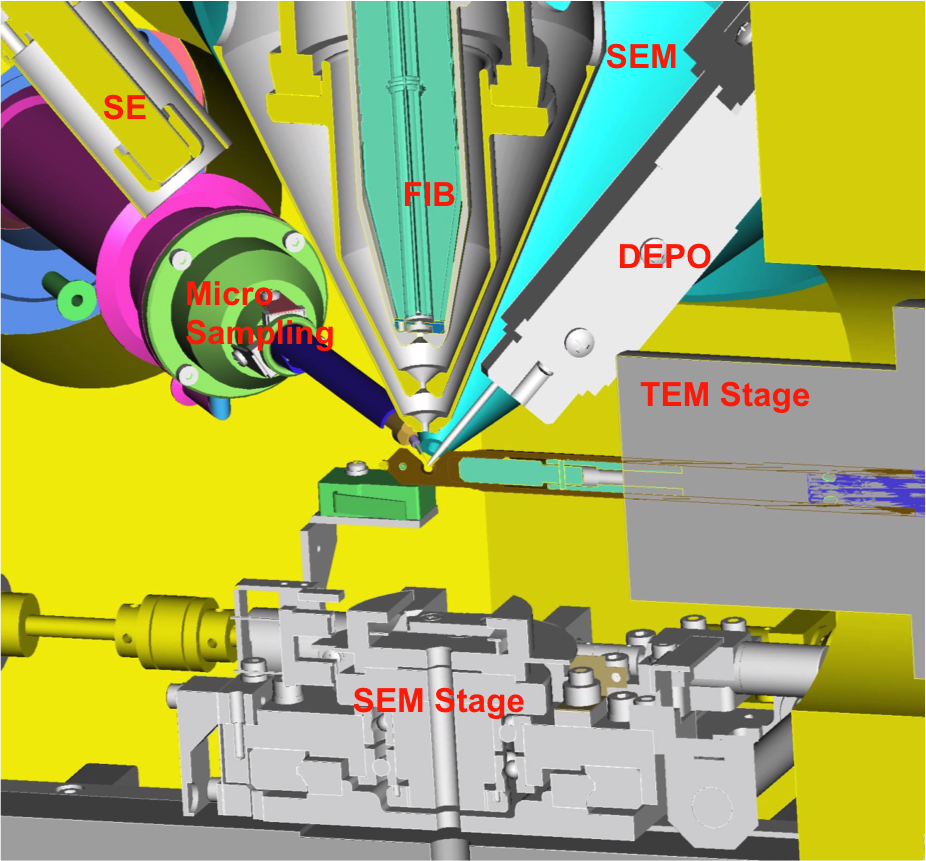

i-beam:

40-2.0 kV, <5nm spot size

i-beam:

40-2.0 kV, <5nm spot size

(+) machine/deposit

(-) implantation/damage (not ideal for imaging)

e-beam:

30-0.5kV, 0.8nm spot size

(+) no implantation/damage (ideal for imaging)

(-) slow machining/deposition

e-beam + i-beam = dual beam

i-beam is 58 deg. from e-beam

(+) e-beam images of the FIB prepared cross-section face without moving the stage!

(+) serial sectioning for 3D info. = “slice + view”

(-) very complicated/expensive

|

“Creating partnerships for innovative research”

Open Centre for the Characterisation of Advanced Materials